The Importance of CNC Custom Automotive Machining

CNC custom automotive machining plays an integral part in driving innovation in the auto industry, enabling car companies to design components explicitly tailored for specific vehicle models that improve both safety and performance. The actual Interesting Info about CNC auto parts.

Machining is an efficient and reliable method for producing precise auto parts quickly. However, only those dimensions critical to their function should be controlled when doing machining work.

Precision

Precision is at the core of custom automotive parts fabrication. Machinists use computer-aided design (CAD) software to craft detailed blueprints of desired components, then utilize precision machinery for cuts, drills, and mills with unparalleled accuracy – significant when producing automotive parts that need to fit within an exacting tolerance for proper functionality for years down the line.

Custom machining’s combination of accuracy, detail, and repeatability makes it the ideal method for producing many automotive components. Custom machining is particularly popular among vintage car owners looking for replacement parts, while its precision also enables industry players to test effectiveness and safety before placing products on the road.

CNC machining can be used to manufacture parts made of various materials ranging from metals and plastics. Its use is beneficial for producing components requiring high levels of accuracy or precision, such as engine parts or headlights while creating unique shapes with various finishes essential in creating customized vehicles.

Precision machining can also be used to craft customized wheel discs or hubs, adding an element of elegance and sophistication to any vehicle. They can be created from materials like aluminum or bronze for durability and a beautiful appearance – perfect for classic or luxury models alike.

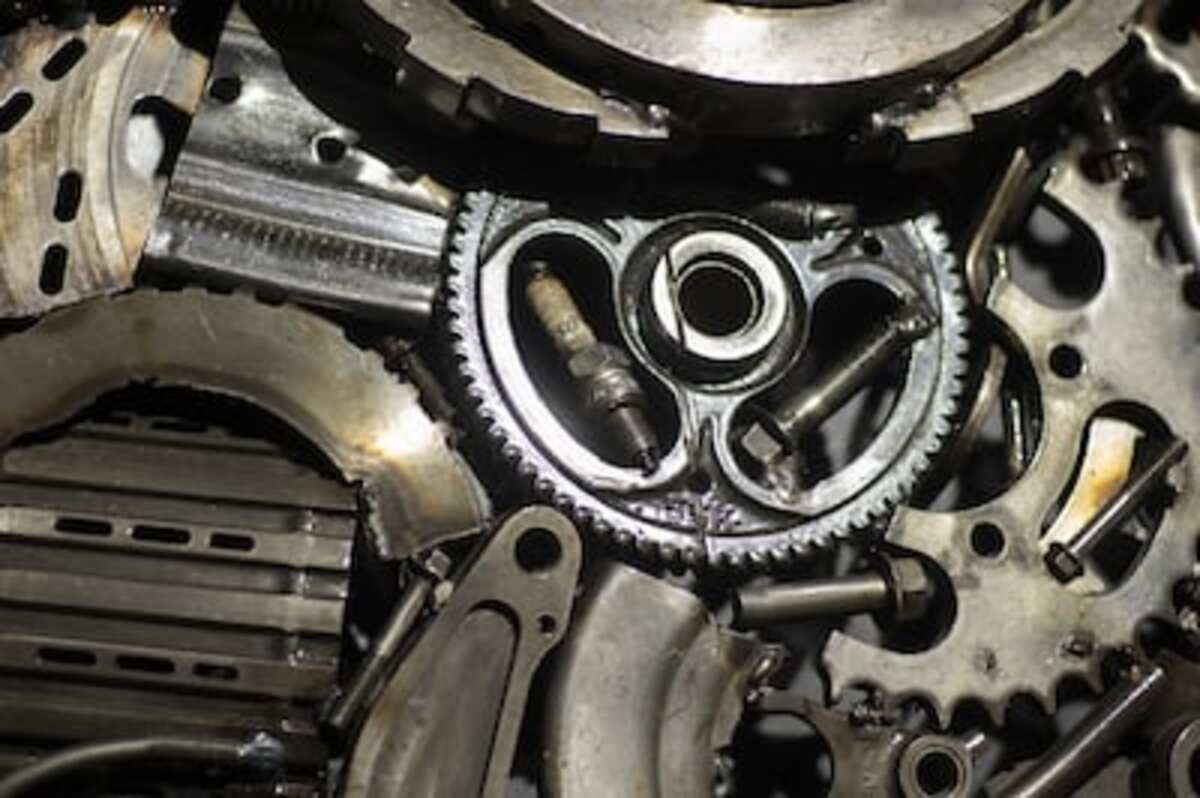

Other custom-machined auto parts include fluid system components, carburetor housings, suspension components, and cylinder heads. These pieces often consist of expensive metals requiring high-precision manufacturing; aerodynamic components like gears must conform to specific shapes and sizes to maximize performance and reliability.

If you need precision auto parts made, look for a company willing to partner with you from start to finish. From CAD programming through prototyping and final production, the right partner should treat you more as a partner than simply another client. Consider companies offering comprehensive services and equipped with equipment capable of producing quality results.

Safety

CNC machining car parts is an increasingly popular practice among car enthusiasts looking for ways to personalize their ride and enhance driving experiences. CNC-machined components can add a personalized touch, from small changes in part shapes to custom cutouts for indicators or other features.

CNC Machining provides an ideal solution for meeting all types of automobile manufacturing production requirements, with its rapid production times and high level of precision ensuring parts meet stringent automotive industry standards.

Automotive CNC machining is an ideal production technique for creating prototypes of automobile components, enabling testing before total production begins. This is particularly helpful for automobile manufacturers looking to optimize and fine-tune their products prior to mass production.

Automotive CNC machining serves a number of other purposes in addition to concept modeling, such as creating physical prototypes for design verification. This critical step helps engineers ensure their designs fit and function as intended.

Additionally, for an engine to function optimally, its cylinder heads and pistons must undergo precise CNC machining in order to function. This ensures all internal passages for air, oil, and coolant are correctly positioned. Gears also play a vital role in engine performance by providing torque adjustment capabilities as well as speed adjustment, often created using CNC to ensure tight tolerances are met during fabrication.

Automotive CNC machining offers fast production times and impeccable precision that make it essential to any industrial-grade manufacturing process. When combined with experienced teams of engineers, this production method ensures all auto parts produced are roadworthy.

Sustainability

Accurate and fast production of components meeting specific specifications is vital in many industries, including automotive. Custom machining plays a pivotal role here; custom engine parts and transmission components manufactured through custom machining can dramatically enhance vehicle efficiency and performance while being less prone to wear and tear than their non-custom machined counterparts, leading to decreased replacements, lower energy consumption, and lowered costs overall.

CNC machining’s precision helps reduce production waste, making it more eco-friendly than other methods, such as 3D printing. Furthermore, its cost-effectiveness makes it more suitable than alternative fabrication techniques like 3D printing. Furthermore, its versatility enables it to work with both steel and aluminum materials, providing sustainable options for prototyping as well as mass production of automotive components in mass quantities – an attractive prospect in any industry.

Efficiency is of utmost importance in the automotive industry, ensuring sufficient cars are produced to satisfy consumer demand. This is especially critical during machining and assembly processes, where efficiency reduces the manual effort needed by workers, while automated processes help decrease material waste to boost productivity further.

CNC machining for automotive applications can help manufacturers embrace sustainability. CNC can be a helpful way of producing lightweight metal parts like engine cylinder heads made from aluminum blocks; alternatively, it could also have alternator housings and brake system valves.

Custom machining’s versatility makes it a valuable asset across industries such as aerospace, defense, automotive and medical. Custom machining can produce intricate aircraft and spacecraft components designed to withstand extreme conditions, while in healthcare, it is used to manufacture specialty instruments and implants, which improve healthcare delivery, while oil and gas sectors use it for producing tailored components for drilling equipment and production machines. As technology evolves further, it will only continue its presence and evolve along with it.

Efficiency

Automotive manufacturing requires efficiency. Production methods should produce high-quality products with minimum waste and fast turnaround times; automated CNC machining has rapidly revolutionized this process and changed how auto-making operates.

Automation of the machining process enables automakers to speed up production time and reduce operational costs, ultimately helping them remain cost-competitive in their markets while offering lower vehicle prices to consumers.

Automation not only increases productivity but also enhances quality and consistency in automotive parts production. This is vital as auto-makers require their shows to meet strict safety regulations while meeting quality expectations. CNC machining provides an efficient yet precise means of producing such components from an array of compatible materials.

CNC machines offer multiple advantages over their human counterparts for manufacturing large volumes of components rapidly. CNCs can be programmed to perform repetitive tasks automatically, freeing human operators to focus on other aspects of production while automating machining reduces errors and ensures uniform quality across production runs.

CNC machining provides a reliable way to manufacture engine components essential to car performance, such as engine blocks, intake manifolds, and cylinder heads made of various cast aluminum alloys, as well as lightweight metal parts like exhaust parts or carburetor housings.

CNC machining offers several critical advantages for automotive companies. One is its speed in producing high-quality prototypes quickly; this enables testing and fine-tuning before entering full production mode. Furthermore, this technology can also be utilized for making various interior and headlight components.

Customizing their cars is an effective way to express personal expression while adding an individual touch and a secret word. Furthermore, customized auto parts can also enhance performance and handling capabilities – although, for optimal results, these modifications must be accurate and durable.

Read also: Free Samsung Government Phone